Thursday’s Mesaba hearing at PUC is OFF!

May 6th, 2008

Nevermind about coming to the PUC Hearing on Thursday.

First you say you will, and then you won’t

Then you’ve got a hearing… and then you DON’T…

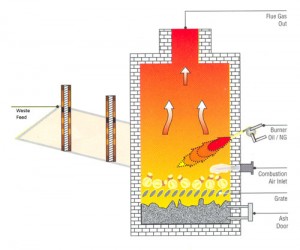

Yes, here we go again. Excelsior Energy, the denizens of desparado, finagled yet another delay, this from the guys who didn’t want to sit still at the beginning. IGCC, coal gasification, by any name it’s a disaster… yet it drags on and on and on and on. Here’s what they filed this afternoon:

And even later this afternoon, this came out from the PUC’s Janet Gonzalez:

Parties and interested persons:

Item #6, Oral Argument and Deliberations on Excelsior-Phase 2, Docket E-6472/M-05-1993 has been pulled from the Minnesota Public Utilities Commission agenda of May 8, 2008.

It will be rescheduled at an as yet unspecified date after the period for reconsideration has run out, or the Commission takes action on any petitions for reconsideration that may be filed, of its April 23, 2008 ORDER DENYING REQUEST FOR INDEFINITE STAY in this docket.

Janet F. González, Energy Unit Manager

Minnesota Public Utilities Commission

Like with poor Eight Bells, it’s time. It’s gotta happen. Will somebody just do it and put us all out of our misery?!?

Comments on Gov’s Greenhouse Gasbags’ Report

May 6th, 2008

The Comments sent in on the Green Chameleon’s Gov’s Greenhouse Gasbags’ Report are out. Oh, translation for those not keeping up, the Green Chameleon is Gov. Tim Palwenty, because he talks the talk and walks in the other direction and too few are watching and comparing. The Minnesota Climate Change Action Group members are the Greenhouse Gasbags because in their recommendations, they promote increased generation of CO2, which is counterproductive and goes against their charge under the statute. Aaaaah, but what do they care, they’ve got a job to do, which apparently is to assure that there’s no “impediment” to Big Stone II and Excelsior Energy’s Mesaba Project. Here are the comments received:

What a great showing — 63 pages of comments, many of them objecting to the exemption of Big Stone II and Mesaba from regulation. YESSSS! They sure need to be slapped upside the head for that lame-brained idea, and you missed the increase of burning biomass??? I don’t think so…

MPCA Solid Waste “Stakeholder Process”

May 2nd, 2008

I received Notice yesterday from the MPCA of a Proposed Stakeholder Process, soliciting comments on it. Yes, of course they’ll get Comments, but what struck me was that 1) I was on the list, and 2) so many others weren’t on the list. So it seems to me it’s important to get word out about this.

Here’s the proposed stakeholder process:

The “stakeholder” list is very short. If you’re interested in receiving further information, email ALL these folks and tell them you didn’t get notice of the “2008 Part 4 Stakeholder Process” and that you should be added to the list:

tim.scherkenbach@state.mn.us

brad.moore@state.mn.us

tina.patton@state.mn.us

This “Stakeholder Process” group is yet another of those toady groups like the Govs. Greenhouse Gasbags Group (MCCAG) that signed off on dreadful policy, for example exempting Big Stone II and Mesaba IGCC from CO2 regulation.

PROPOSED STAKEHOLDER PROCESS

COMMENT DEADLINE

4:00 P.M.

MAY 13, 2008

Send comments to:

tim.scherkenbach@state.mn.us

brad.moore@state.mn.us

tina.patton@state.mn.us

This new stakeholder group, under the proposed process, has a “Steering Committee” and one of their specific tasks is to “establish process outcomes.” Oh, OK, well, if you establish the outcome, what’s the point of the process where outcome is predetermined? Another problem is that it “MAY” utilize the Gov’s Greenhouse Gasbags’ recommendations…

… and it “MAY” utilize the 2007 Solid Waste Policy Report:

Both of these reports are problematic regarding solid waste — both recommend increased burning of “biomass” which is highly polluting and there just isn’t enough “clean wood” to go around and they burn stuff that’s even worse than the already polluting “clean wood,” like old junk pallets, C&D waste, and GARBAGE. In Minnesota, under statute, mixed municipal solid waste (MSW) and refuse derived fuel (RDF) is deemed “renewable.” Biomass can be up to 1/3 garbage! Great, just great.

Anyhoo, Comments on the proposed “Stakeholder” process are due in about two weeks. Get to it!

Read the proposal: 2008 Part 4 Stakeholder Process

PROPOSED STAKEHOLDER PROCESS

COMMENT DEADLINE

4:00 P.M.

MAY 13, 2008

Send comments to:

tim.scherkenbach@state.mn.us

brad.moore@state.mn.us

tina.patton@state.mn.us

“Hydrogen embrittlement is a major cause of fastener failure”

April 30th, 2008

The day before yesterday, the Wabash River IGCC’s pet coke gasifier blew up, or had a majorly pressurized blast (did it ignite? not sure…) that was felt and heard far beyond the plant boundaries. A cover over a flange opening “failed” and it failed while two workers, Danny Turner and David Shoemaker, were tightening bolts 150 feet up in the air. They were killed, and there have not been reports of other workers injured, nor has there been a statement that there were no other casualties, so we don’t know…

Anyway, a little birdie sent me a link, with the hypothesis that hydrogen embrittlement may be related to the failure. Here’s the link:

And here’s the short version, taken directly:

Hmmmmmm, makes sense to me! A quick google brings up a boatload of references, the second one is:

Hydrogen embrittlement of high strength fasteners

The following inspection and management practices associated with bolted connections are recommended:

1. Locate and document all corroded bolted connections during external visual inspections of equipment and piping, especially inspections preceding a scheduled maintenance shutdown. Corroded, high strength fasteners should be replaced during the outage and protected with a barrier coating, anti-seize compound or rust preventative.

2. Incorporate inspection of bolted connections in risk-based inspection management programs.

3. Include provisions in maintenance management procedures to protect newly installed fasteners from corrosion.

The role of counterfeit fasteners in fastener failures has received much publicity. A potentially greater hazard in the sudden failure of fasteners due to hydrogen embrittlement is less well appreciated.

So it sounds like the little birdie is on to something here. Google yourself and check it out!

Direct Action!

April 29th, 2008

A couple months ago, I was at my neighbor’s coffee shop, The Galley Room on Main Street in Red Wing, and i saw a stove that looked just like the one I had at 2806 – 12th Ave So., I lived there for three years or so. I really liked it, and the one I have now is so blah, so spur of the moment, I bought it. Then Ann at Ferrin’s had told Deb she wanted to use it for her Christmas window, so there it was for a couple of months, focus of a cute winter scene. Now that we’re back, it was time to have it delivered. So, here it is, and the name, which I hadn’t noticed (it was THAT spur of the moment, name, who cares, I WANT IT!), it’s name is: DIRECT ACTION! How appropriate! So that’s the next project, after the bathroom is up and running, and it looks like the toilet and sink may be functional today. The largest of the bathtub parts arrived UPS today. Soon, though it won’t be next to the window, it has to be on the other side to get the plumbing to it: