It’s all about coal… as if there was any doubt!

July 24th, 2018

That’s the Coal Creek coal plant in North Dakota. Back in late August 2006, I got on the bus and went on the tour of the coal plant and the Falkirk coal mine. Well worth it! Anyway, google alerts caught this article recently:

North Dakota coal plant to upgrade transmission system that carries power to 500,000 people

UNDERWOOD, N.D. — Greg Schutte compares Great River Energy’s current transmission system to an 8-track tape and the improvements being made as upgrading to the latest iPhone.

The CU HVDC line, which stands for high voltage direct current, was put in service 40 years ago in 1978.

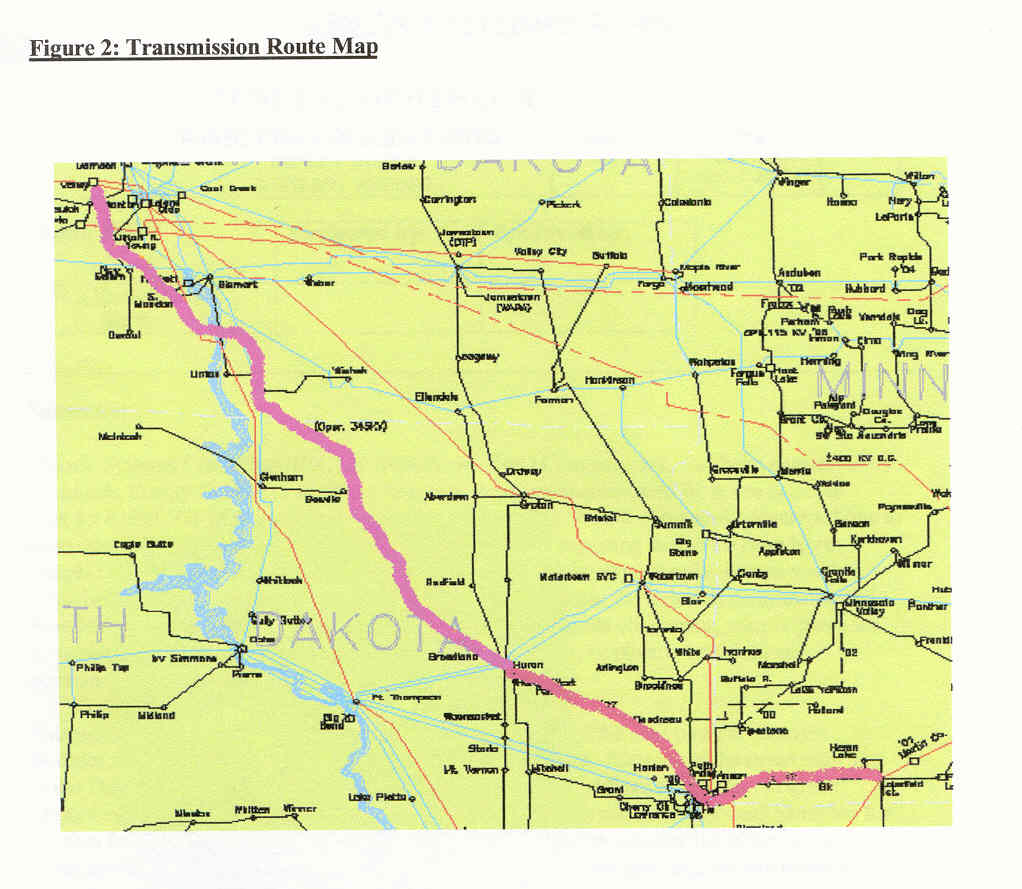

It’s an extremely important line to GRE because it moves 73 percent of the cooperative’s power supply 436 miles from Underwood to Buffalo, Minn., west of the Twin Cities, and serves about 500,000 customers across Minnesota and parts of Wisconsin.

The power cooperative is preparing to invest $130 million in the line, which Schutte said is imperative to continue producing power at the state’s largest coal-fired power plant, Coal Creek Station.

“It’s an investment in the station and an investment in Coal Creek Energy Park,” Schutte said.

“We had inklings the stations were getting too old,” Schutte said, so GRE performed a life assessment on the system. “We found out we had some issues.”

The main concern is with the thousands of valves located within the conversion equipment, all of which are oil lubricated. The newer technology changes that, making the valves fireproof and reducing risk of failure.

So in 2015, GRE awarded a contract to ABB, a Swedish company, to replace the system.

Starting in March [2019], the power plant and transmission system will go through a 74-day outage, running at half power for all but three days of total shut down. In that time, ABB will gut and reconstruct the two 65-foot stacks that convert the power for transport across the line.

“We’re basically just keeping a shell,” Schutte said. “That’s a huge outage for us.”

GRE began the process seven or eight years ago and, in the past couple years, has devoted more than 20,000 internal engineering hours to making the conversion run smoothly.

A 350-by-100-foot building is being constructed on site to serve as a staging area as the equipment is shipped from overseas. The contractors will pre-assemble as much as possible.

“They want to be really focused once the outage starts,” GRE spokesman Lyndon Anderson said of crews that will be running 24/7.

More than 100 union contractors will be on site.

“It’s the biggest project on our books,” Anderson said.

Along with the valves, the computers that control the system, “the brains of it,” are being replaced, according to Schutte.

The components that make up the system will be reduced by 70 percent, which means less moving parts to maintain.

The system also will see a 7-megawatt efficiency gain because it will be water cooled rather than air cooled. Currently, GRE has to power 1,000-horsepower worth of fans that force air through the system. With the updates, they can sell that power rather than using it.

“That’s nothing to shake your head at either,” Schutte said.

Once the project is complete, the staging building will become a shop for the line and substation maintenance crew. ABB will stay on site for a 90-day trial operation after the outage.

Schutte said there are only five transmission lines in the United States like the CU HVDC line and it’s one of the oldest. The only remaining one that will need updating is Minnesota Power’s Square Butte, HVDC line, which also runs through North Dakota between the Minnkota Power Cooperative’s Milton R. Young Station and Duluth, Minn. Schutte predicts that line is about four years behind GRE’s for updates.

GRE’s line has been extremely reliable, running nearly 100 percent of the time, according to Schutte. Without the updates, it was predicted that reliability would drop off next year and the cooperative wanted to be ready for it.

The last major development by GRE was the building of the Spiritwood Station, which had a $437 million price tag. The cooperative’s DryFining technology installed at Coal Creek cost about $285 million.

Other area transmission projects have involved new construction. Basin Electric Power Cooperative recently finished a 345-kilovolt line from Beulah to Grassy Butte and Tioga at a cost of $300 million, according to Basin spokesman Curt Pearson.

Mark Hanson, a spokesman for Montana-Dakota Utilities, said MDU is splitting the cost of a $240 million to $300 million 345-kilovolt line between Ellendale and Big Stone City, S.D., with Otter Tail Power Cooperative.

Note that the little 200MW Stanton coal plant is closing right now:

Life cycle of lignite plant powers down

ABB, as above, got the Coal Creek job — here’s some of their PR:

CU HVDC Project – Stability over long distances and low environmental impact

ABB wins $130 million order to upgrade HVDC power transmission link in the US

There’s been a lot of new transmission built in the Dakotas, and now they’re going to rehab the CU line?

Remember ABB? They’re the ones who did the study way back when to figure out how best to get new coal generation out of the Dakotas:

And GRE’s coal drying operation, here’s an article I found while looking for details on the Coal Creek rehab:

Lignite and sub-bituminous coals from western U.S. contain high amounts of moisture (sub-bituminous: 15 to 30%, lignites: 25 to 40%). German and Australian lignites (brown coals) have even higher moisture content, 50 and 60%, respectively. The high moisture content causes a reduction in plant performance and higher emissions, compared to the bituminous (hard) coals. Despite their high-moisture content, lignite and sub-bituminous coals from the Western U.S. and worldwide are attractive due to their abundance, low cost, low NOx and SOx emissions, and high reactivity. A novel low-temperature coal drying process employing a fluidized bed dryer and waste heat was developed in the U.S. by a team led by Great River Energy (GRE). Demonstration of the technology was conducted with the U.S. Department of Energy and GRE funding at Coal Creek Station Unit 1. Following the successful demonstration, the low-temperature coal drying technology was commercialized by GRE under the trade name DryFining TM fuel enhancement process and implemented at both units at Coal Creek Station. The coal drying system at Coal Creek has been in a continuous commercial operation since December 2009. By implementing DryFining at Coal Creek, GRE avoided $366 million in capital expenditures, which would otherwise be needed to comply with emission regulations. Four years of operating experience are described in this paper.

(PDF) Four Years of Operating Experience with…. Available from: https://www.researchgate.net/publication/282203428_Four_Years_of_Operating_Experience_with_DryFiningTM_Fuel_Enhancement_Process_at_Coal_Creek_Generating_Station [accessed Jul 23 2018].

Leave a Reply